Drastic increase in cybersecurity discussions is one thing that many of us in the security industry didn’t predict for 2016. Cybersecurity has obviously always been an important issue in general, but the discussion has gained a lot of momentum in the past year.

As I said, this wasn’t predicted by most of us in the industry. The intensity of the focus on and discussion around cybersecurity in 2016 was a response to some of the high-profile denial of service (DoS) attacks that occurred in 2016, especially the Mirai malware attacks on IP-based NVRs and network cameras in October. We’re still experiencing the effect of these events, but it’s safe to say that there will be greater emphasis on ensuring that back door access to devices no longer exists.

Mirai Malware Attack

In the October Mirai attack, the end users were not even aware of the devices’ vulnerabilities. With the planted malware inside the devices, the hackers were able to launch the attack through the devices themselves. It’s unfortunate, but hopefully the attack draws attention to the importance of every aspect of cybersecurity. For integrators, installers, and end users, we need to place more emphasis on knowing suppliers and what devices are and are not capable of doing.

Otherwise, our perspective last year on what 2016 would hold was quite accurate. Last year, we predicted that the industry would see the rise of the smart/safe city in 2016 and that interoperability would become even more important. On both counts, the prediction was correct. We’ve seen continued development in the smart city space in 2016 and even greater demands for interoperability.

|

| Businesses will have to adapt to these new interoperability demands and market conditions or they risk losing out |

The demand for interoperability and open systems and standards will increase in 2017. It’s a growing demand that doesn’t seem to be slowing down, particularly as more and more systems and devices require standardized communication. Businesses will have to adapt to these new interoperability demands and market conditions or they risk losing out. That’s true within the physical security industry and in most technology-based markets.

De Facto Standard For Interoperability

In 2016, ONVIF continued to mature as an organization. ONVIF has really established its position as the de facto standard for interoperability between IP-based physical security devices. This has happened due to the widespread adoption of its Profiles and specifications by the physical security industry and by other standards groups like the International Electrotechnical Commission (IEC).

In looking ahead to 2017, we’re confident that ONVIF will continue to maintain that position as the de facto standard for IP-based physical security devices. ONVIF will develop Profiles to address the current needs of the industry and also will continue its work with groups like the IEC, adapting broader standards to reflect updates to ONVIF’s specifications.

See the full coverage of 2016/2017 Review and Forecast articles here

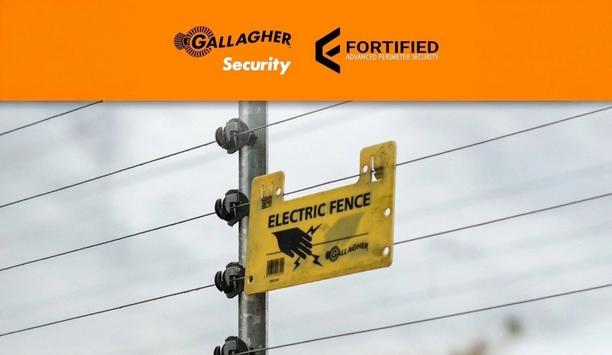

Find out about secure physical access control systems through layered cybersecurity practices.