Each day, over 55,000 electrical substations in the United States funnel massive amounts of energy to homes and businesses across the country. An array of specialized equipment allows these facilities to keep up with demand, and each component must run smoothly to adequately transfer and distribute energy.

Housing mission-critical assets vital to the community means that substations must track everything—from condition monitoring to intrusion and sabotage threats. Thermal imaging cameras, video classification analytics, and radiometric measurement offer unmatched maintenance and security insight for substations and help prevent costly issues that hurt the bottom line.

AI and deep learning technologies

Advancements in artificial intelligence technologies are expanding the capability of security systems

Advancements in artificial intelligence and deep learning technologies are expanding the capability of security systems. As security solutions improve, customer expectations grow. Systems that were once limited to perimeter protection are now able to provide valuable process efficiency and maintenance information. Substations should consider integrating new technology that improves efficiency and safety as they move to satisfy NERC CIP-014 requirements.

Problematic heating and cooling connections can plague substations. Overheating and burning a transformer is a costly, potentially multimillion-dollar error that can take several months to correct. Beyond damage costs, the abrupt loss of equipment can lead to extended service interruptions and significant revenue loss. The consequences of equipment failure highlight the importance of asset monitoring, asset resiliency, and predictive maintenance for substations.

Radiometric thermal cameras

Integrating cutting-edge technologies like radiometric thermal cameras and temperature trend analysis software allows facility operators to remotely inspect equipment and quickly detect issues, preventing overheating and fires. Image quality and software compatibility are vital in planning an asset monitoring ecosystem.

To best serve both the security and condition monitoring needs of substations, thermal sensor manufacturer FLIR Systems and software developer Embedded Logix collaborated to create a multi-purpose solution.

Security and asset monitoring

For over 30 years, FLIR has developed security and asset monitoring solutions for utility providers

For over 30 years, FLIR has developed security and asset monitoring solutions for utility providers. A full lineup of fixed and pan-tilt thermal cameras allow security operators to monitor assets and perimeters in complete darkness, smoke, fog, and harsh weather conditions.

FLIR thermal cameras provide superior resolution, capturing sharp imagery and minute details for high-performance video analytics and immediate threat detection. Quick intervention during intrusions prevents escalation, and rapid detection with thermal imaging supports fast response time.

Smart-LX Sensor Gateway

Recognizing threats before they ever reach the fence line deters theft, vandalism, and assault, keeping facility personnel safe and reducing the risk of equipment repair and legal costs. As an industry leader in thermal imaging, FLIR looks to partner with other innovative solution providers to create more advanced technologies.

Embedded Logix, a Detroit, Michigan-based test and measurement solutions provider for the utility, plastic, food, and metal industries emerged as an ideal partner to integrate smart analytics software into thermal sensors. Their Smart-LX Sensor Gateway is an open-architecture platform that features Smart-LX Analytics with support for infrared cameras, programmable logic controllers, and SCADA systems. It opened the door for a complete predictive maintenance solution.

FLIR thermal cameras

Partnering with FLIR means being in the center of the infrared universe"

The Smart-LX system allows both maintenance and security personnel to leverage networked thermal imagers on a single platform. By 2012, Embedded Logix was FLIR’s exclusive smart sensor software partner for temperature trending in predictive maintenance, bringing the Smart-LX platform to FLIR thermal cameras.

“Partnering with FLIR means being in the center of the infrared universe. We can’t imagine any better product lineup to feed data into our Smart-LX Analytics,” said Deborah McLeod, president of Embedded Logix. “We have bench tested many other brands over the years, but FLIR’s products always come out on top, and that is why we recommend FLIR cameras to our customers. When you combine Smart-LX Analytics with FLIR cameras you turn an incredible sensor into an extraordinary solution.”

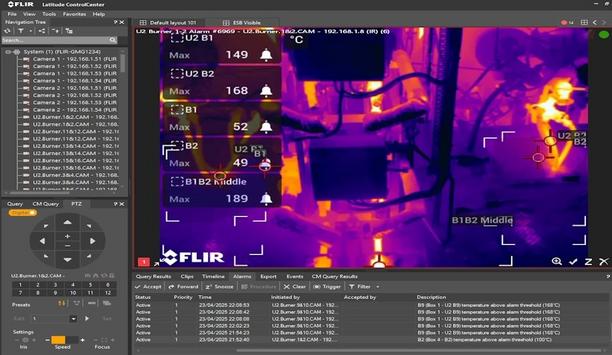

Smart-LX Analytics

Embedded Logix Smart-LX Analytics read, process, analyze, and create a visualization of sensor readings, generating asset performance reports on trends and rules that can be sent to maintenance personnel for further assessment. The software adapts over time with customer input, relying on user feedback to create an expert system. The Smart-LX platform works with both legacy and new equipment, analyzing signals from all sensors and systems, and is capable of aggregating information into VMS, OSI PI, and SCADA platforms.

The FLIR FC-R fixed thermal camera leverages a radiometric sensor for noncontact temperature measurement

FLIR offers several high-performance thermal imaging solutions for Smart-LX integration, including the FLIR A310 and FLIR FC-R Series cameras. Dual thermal and optical sensors on the FLIR A310 PT offer reliable perimeter protection and automated condition monitoring while pan/tilt controls maximize coverage. The onboard radiometric thermal sensor measures slight changes in surface temperature, allowing the A310 PT to monitor hotspots on equipment and alert an operator if temperatures exceed preset levels.

FC-R fixed thermal camera

The FLIR FC-R fixed thermal camera leverages a radiometric sensor for noncontact temperature measurement. Onboard human and vehicle classification analytics offer reliable intrusion detection and work in tandem with external monitoring systems to quickly alert operators and security personnel.

“FLIR’s innovative A310F, A310PT, and FC-R radiometric thermal cameras have been paramount in substation monitoring for years,” said Michael Chaffee, director of business development at FLIR. “With the addition of Embedded Logix and its SmartLX software, our customers can take FLIR thermal cameras to the next level. When combined, FLIR cameras and Smart-LX software create a data goldmine, allowing a more frequent analysis of substation assets right from the security control room.”

Facility security

FLIR and Embedded Logix systems revolve around facility security and asset monitoring

FLIR and Embedded Logix systems revolve around facility security and asset monitoring. Installing different cameras and network components throughout a substation creates an ecosystem ready to detect and prevent issues. Most security and asset monitoring systems from FLIR and Embedded Logix begin with several FLIR FC-ID cameras along the perimeter of the substation, one A310 PT mounted in the center of the substation, FC-R or A310F cameras installed around high priority assets, and several Smart-LX Sensor Gateways.

When the system detects an object of interest, FLIR FC-ID cameras trigger the A310 PT camera to track and zoom on the object for further threat assessment, allowing security personnel to quickly and safely gauge the situation. Condition monitoring thermal imagers can continuously survey any asset in their field of view.

Fixed FLIR A310F camera

Fixed FLIR A310F and FC-R cameras monitor specific equipment 24/7, while the A310 PT can focus on multiple areas, viewing transformer connections, incoming power transmission lines, switch gears, fans, and more.

Generated reports compare the performance of similar assets across all stations

Smart-LX Sensor Gateways control the A310 PT preset scanning to gather temperature information on equipment, triggering an alarm if a temperature exceeds the preset threshold. Generated reports compare the performance of similar assets across all stations, address historical temperature trends, and label each temperature reading with the substation location, asset ID, and asset class information. This reporting is vital, as temperature trends can indicate trouble even when alarms remain untriggered.

Remote monitoring

“If the temperature is rising and falling on one asset, but the temperature on the other assets are steady, it can indicate a problem,” McLeod explained. “Even if the asset doesn’t reach the temperature threshold, the temperature slowly creeping up to that threshold is valuable information.”

FLIR and Embedded Logix systems leverage remote monitoring to catch issues before they occur, preventing expensive downtime and maximizing substation efficiency. Predictive maintenance programs can identify poor-performing components, allowing operations teams to decide whether to proactively replace components or to continue monitoring. An unknown failure could cause catastrophic damage to other substation elements, causing customer outages and costing the utility millions of dollars.

Thermal imaging

Smart-LX Sensor Gateways also allow thermographers to inspect equipment remotely

“The FLIR and Embedded Logix solution allows you to qualify with more frequency,” said Chaffee. “It ultimately enables you to save money and identify failures sooner. It’s much more expensive to replace a component after failure versus pre-failure. When a failure happens, you shut down the substation and part of the grid, which costs a lot of money.”

Smart-LX Sensor Gateways also allow thermographers to inspect equipment remotely, improving efficiency during repairs. Traditionally, a thermographer would report to a substation to manually inspect equipment in need of service. Using a handheld thermal imager, the thermographer would take temperature measurements and check for load balance to determine whether equipment should be taken offline for repair. The need for a pre-work assessment and post-repair verification can make for long days. Embedded Logix Smart-LX Sensor Gateways remove this pain point.

Live data access

The Smart-LX Sensor Gateways give thermographers the ability to inspect equipment remotely and access live data from each networked FLIR thermal camera. Real-time temperature measurement and analytics allow the maintenance crew to confirm repairs or safely identify any additional issues.

Thermographers would only need to go to a site when something is critical"

“The FLIR and Embedded Logix solution enhances the role of thermographers,” Chaffee said. “Not needing to drive hundreds of miles to do a regularly scheduled thermal scan saves a lot of money. Your thermography team can scan safely, and with more frequency, from the security operations center. Thermographers would only need to go to a site when something is critical. Time is money, so being more productive as a utility and building a substation predictive maintenance program is an important element.”

Critical asset monitoring

Smart-LX Software works continuously to monitor critical equipment and uncover even small changes that can indicate impending failure. Intelligent maintenance and security systems are making substations safer and more efficient, positively impacting the bottom line. The insurance deductible of a significant substation asset can be hundreds of thousands of dollars. Detecting just one instance of equipment failure can prevent inordinate costs.

“The Smart-LX Software solution reduces the cost of an event by detecting it much earlier. Instead of detecting a fire, you’re preventing a fire,” McLeod added. “It’s important for all stakeholders that utilities monitor changes in asset health as a means of improving reliability and reducing the total cost of repairs.

Asset security and management

Utilities are moving towards proactive deterrence and away from reactive monitoring

He adds, “Stakeholders want to see that steps are being taken to reduce insurance claims from unnecessary escalations when a malfunctioning asset is not discovered until it fails and takes out expensive assets or infrastructure around it. Preventing costly downtime by repairing equipment at the first sign of trouble can reduce the number of unscheduled downtime events dramatically and create significant cost-savings.”

Leveraging radiometric thermal cameras and analytics for both security and asset monitoring represents a paradigm shift. Utilities are moving towards proactive deterrence and away from reactive monitoring.

Substation security

FLIR radiometric thermal cameras and Embedded Logix Smart-LX Sensor Gateways safeguard substations and reduce the risk of critical equipment failure. Investing in stronger security keeps substations and their assets safe, and innovative, multipurpose solutions from FLIR and Embedded Logix create a win-win for utility providers throughout the country.

Learn why leading casinos are upgrading to smarter, faster, and more compliant systems