FLIR Systems Video Servers (IP Transmission) / Video Encoders (5)

Browse Video Servers (IP Transmission) / Video Encoders

- Make

- FLIR Systems

Video server (IP transmission) products updated recently

Video servers (IP transmission) - Expert commentary

It took just seven minutes to steal more than $100 million in jewels from the Louvre, in an operation so swift and precise it exposed a deeper flaw in how even the most secure inst...

It is the time of year when city centers transform, as outdoor Christmas markets fill town squares and high streets. An estimated 6,000 markets will open across Europe during the f...

Seven minutes. That’s how long the recent Louvre heist took. In broad daylight, a group of thieves rode up on a construction platform, smashed display cases, stole several hi...

Latest FLIR Systems news

At CES 2026 in Las Vegas, demonstrations of Flir’s next-generation iXX-Series app-enabled thermal cameras will outline how users can transform electrical and mechan...

Acoustic imaging offers a powerful early warning solution, enabling operators to detect issues before they escalate and keep turbines running efficiently. For any government, sour...

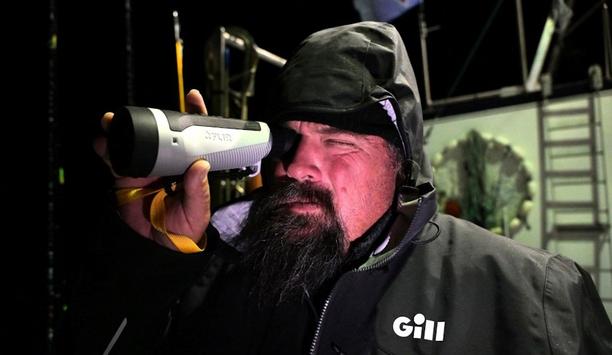

FLIR, pioneer in high-performance marine thermal-imaging systems, is pleased to announce that the Ocean Scout Pro handheld thermal imaging camera, has been awarded top honors...

Related white papers

The Benefits of Edge AI + Cloud For Security Systems

Video Technology: Making Cities Safer & Improving Lives

Choosing the Right Storage Technology for Video Surveillance

Trending topic articles

VITEC, a pioneer in IPTV and digital signage solutions, and Actelis Networks, Inc., a market pioneer in cyber-hardened, rapid deployment networking solutions for IoT applications, now announced a new...

WatchGuard® Technologies now announced the WatchGuard Zero Trust Bundle – a streamlined solution that finally makes zero trust achievable for organizations of all sizes. For y...

Fortinet®, the global cybersecurity pioneer driving the convergence of networking and security, now announced an integrated solution featuring FortiGate VM, Fortinet’s virtual cloud firewall...

dormakaba has signed a binding agreement to acquire Avant-Garde Systems Inc. (“Avant-Garde”), one of the largest independent solution providers for entrance systems control products in the...

Skills for Security has partnered with C-TEC to strengthen the training opportunities for apprentice fire and security technicians through greater access to current technologies and direct engagement...

Opengear, a Digi International company and a pioneering provider of secure and Smart Out of Band™ management solutions, announced now that it has achieved SOC 2 Type 2 and ISO 27001 compliance....

At CES 2026 in Las Vegas, demonstrations of Flir’s next-generation iXX-Series app-enabled thermal cameras will outline how users can transform electrical and mechanical inspections acr...

Allied Universal has sold a majority stake in AMAG Technology to Shore Rock Partners, a critical infrastructure-focused growth investor. AMAG is a global pioneer in integrated high-security access con...

Squire Locks USA has appointed Channel Championz, founded by security industry veteran Jerry Burhans, to lead its expansion into the North American critical infrastructure market. Burhans, a seasoned...

Netwatch, a provider of AI-powered security services, announced now that it has signed a definitive agreement to be acquired by GI Partners. Netwatch is a pioneering global provider of intelligent se...

Alibaba now unveiled the latest evolution of its visual generation models, the Wan2.6 series. It enables creators to appear in AI-generated videos as themselves and in their own voices with flexible...

In recent years, the development and adoption of AI technology has accelerated at an unprecedented pace, impacting various industries. Of course, the spark of innovation provided by AI is already a fe...

Matrix Comsec, a pioneer in Security and Telecommunication solutions, was honored with the CII Industrial Innovation Award 2025, recognizing Matrix as one of the Top 50 Most Innovative Companies in In...

i-PRO Co., Ltd. (formerly Panasonic Security), a pioneer in professional security and public safety solutions, now shared its predictions for the security industry in 2026. The year ahead will contin...

ANSecurity, a pioneering specialist in network security and wireless solutions, has successfully delivered one of the UK education sector’s first campus-wide Wi-Fi 7 deployments at Sir William P...

The Key To Unlocking K12 School Safety Grants

DownloadHoneywell GARD USB Threat Report 2024

DownloadPhysical Access Control

DownloadThe 2024 State Of Physical Access Trend Report

DownloadThe Security Challenges Of Data Centers

Download