FLIR Systems Video Surveillance software (1)

Browse Video Surveillance software

- Make

- FLIR Systems

- Other FLIR Systems products

- FLIR Systems IP cameras

- FLIR Systems Network Video Recorders (NVRs)

- FLIR Systems IP Dome cameras

Video Surveillance software products updated recently

Video Surveillance software - Expert commentary

Where and how to store security camera footage usually depends on the scale of the video surveillance project, the way you are using to record the video and how long you want to ke...

Retailers now often find themself in a precarious situation. Profit margins are being squeezed by widespread shoplifting: The Council on Criminal Justice reports that between the f...

In today's rapidly evolving security landscape, facial recognition has become a buzzword that often triggers privacy and data protection concerns. However, many security professio...

Latest FLIR Systems news

Acoustic imaging offers a powerful early warning solution, enabling operators to detect issues before they escalate and keep turbines running efficiently. For any government, sour...

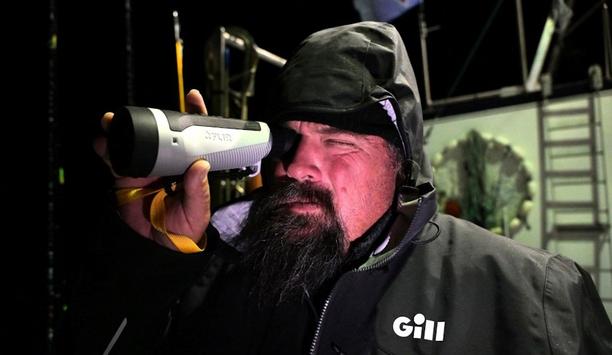

FLIR, pioneer in high-performance marine thermal-imaging systems, is pleased to announce that the Ocean Scout Pro handheld thermal imaging camera, has been awarded top honors...

Flir, a Teledyne Technologies brand, announced built-in GPS for its Si2-Series acoustic imaging cameras. The upgrade adds precise location data to predictive maintenance inspectio...

Related white papers

The Benefits of Edge AI + Cloud For Security Systems

Video Technology: Making Cities Safer & Improving Lives

Unified Physical Security

Trending topic articles

Alcatraz, the pioneer in facial biometric authentication for physical access, now announced the successful completion of its SOC 2 examination as of November 7, 2025. The independent audit was conduc...

Datalogic, a pioneer in automatic data capture and process automation, will demonstrate how its integrated portfolio is empowering the intelligent store at NRF 2026, thanks to AI-driven integration....

Deep Sentinel, the pioneer in AI-powered proactive video surveillance with real-time human intervention, now announced the launch of its Mobile Monitoring Trailer — a fully mobile, solar-powered...

The contract was signed, live at the SPS in Nuremberg, Germany: CADENAS is now the newest member of the Eplan Partner Network. CADENAS Managing Director Terry Jonen and Eplan Managing Director Ha...

AI is one of the fastest-growing technologies in the history of modern business, with the ability to revolutionize industries, optimize operations, and drive innovation, but it is also introducing sec...

Smeup, a key partner for companies engaged in digital transformation, now announced the expansion of its adoption of Cubbit, the first geo-distributed cloud storage enabler, as part of a Business Alli...

WatchGuard® Technologies now announced that its endpoint security solution delivered outstanding performance in the latest MITRE ATT&CK® Enterprise Round 7 (ER7) Evaluation. The results h...

EnGenius Technologies Inc., a pioneer in advanced connectivity and cloud-managed networking solutions, today announced that Crossroads Church in Rowlett, Texas, has completed a comprehensive security...

The Physical Security Interoperability Alliance (PSIA) has now announced the release of a new PKOC Explainer Video, created to offer a clear and visual overview of the Public Key Open Credential (PKOC...

Integrated Control Technology (ICT®), a pioneering provider of intelligent access control, intrusion detection, building automation and security solutions, is pleased to announce the appointment o...

Zimperium, the pioneer in mobile security, today announced new research from its zLabs team uncovering DroidLock, a rapidly evolving Android malware campaign targeting users in Spain. Unlike traditi...

Bugcrowd, a pioneer in crowdsourced cybersecurity, has launched new platform functionality, Bugcrowd AI Triage Assistant and Bugcrowd AI Analytics, to bring unprecedented spee...

HENSOLDT AG announces that Sven Heursch, previously Head of Software-Defined Defense & Digitalization, will be appointed Chief Digital Officer (CDO) with effect from 1 January 2026. In this role,...

Videonetics, the pioneer in True AI-powered video analytics and unified video computing platforms, reaffirmed its commitment to shaping the future of intelligent video technologies at Videonetics...

To serve various vertical markets and industries effectively, security professionals must recognize that each sector has unique assets, risks, compliance requirements, and operational needs. Instead o...

The Key To Unlocking K12 School Safety Grants

DownloadHoneywell GARD USB Threat Report 2024

DownloadPhysical Access Control

DownloadThe 2024 State Of Physical Access Trend Report

DownloadThe Security Challenges Of Data Centers

Download