PCSC Electronic Locks (3)

Browse Electronic Locks

- Lock Type

- Electric Locks

- Electromagnetic Locks

- Shearlocks

- Electric Release Type

- Delayed Release

- Mortice Release

- Rim Release

- Sashlock Release

- Solenoid Bolts

- Yes

- Make

- PCSC

Electronic lock system products updated recently

Electronic lock systems - Expert commentary

The healthcare infrastructure is ever evolving. Facilities are no longer single entities for one, they are sprawling ecosystems that serve a wide range of users, from medical staff...

In today’s connected world, attacks are more likely to target digital than physical entry points. From ransomware and firmware tampering to remote hijacking, AI-driven phishi...

Digital access control has well-known benefits over traditional security, of course, but also costs attached to each stage of its lifetime. However, these costs are not fixed. Many...

Latest PCSC news

PCSC, a designer and manufacturer of access control solutions and Coolfire Solutions, a St. Louis based software company known for creating Military-Grade situational awareness pla...

The BioConnect Identity Platform provides an integration of Suprema's biometric solutions with the majority of leading access control systems BioConnect and Sup...

Systems may be reliable and performing as originally intended, but can also beoutdated in comparison to current technology offerings Let’s start by defini...

Related white papers

The Critical Role of Access Control in K-12 School Security

Three Essential Reasons To Upgrade Your Access Control Technology In 2022

Securing Unmanned Infrastructure at the Network Edge

Trending topic articles

Suprema, a pioneer of AI-powered security solutions, announced that BioStation 3 is expected to set a new annual global sales record by the end of this year. This represents the highest annual sales...

The 19th Real Estate Development Summit Saudi Arabia – Luxury Edition successfully concluded after two days of high-level exchange, strategic collaboration, and global networking, bringing toget...

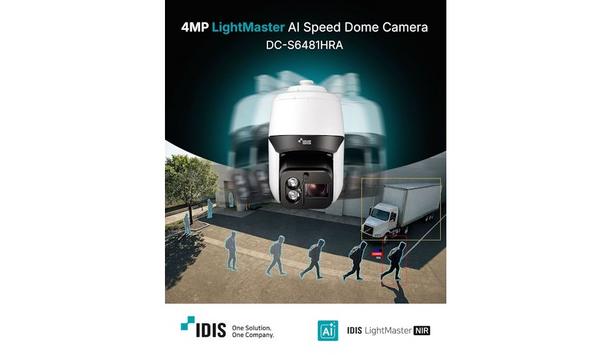

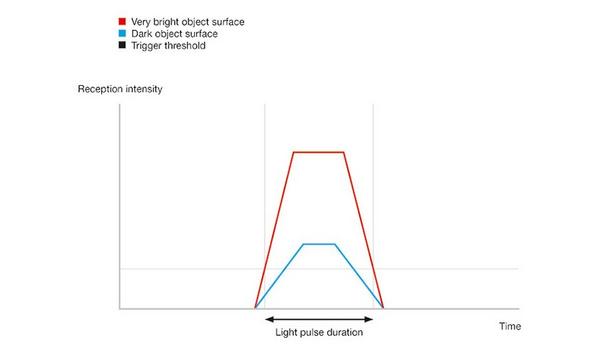

IDIS has launched two new advanced PTZ cameras, providing powerful AI and NIR performance. The extended range offers a broader choice of PTZ cameras to more efficiently cover open areas, in applicatio...

Leuze uses artificial intelligence (AI) to significantly improve the measurement accuracy of optical distance sensors for challenging industrial applications. This innovation improves measurement acc...

Alarm.com and Everon, LLC, a pioneering security integrator and premier provider of commercial security, video, fire, and life safety solutions, today announced a strategic partnership to deliver a un...

Integrated access control and security manufacturer TDSi now announces that from 1st January 2026, it will operate under the new name: TDSi by Hirsch. The change follows the global transformation of...

Aetina Corporation, a pioneering provider of Edge AI solutions, has announced the launch of its next-generation MXM AI Accelerator Module series accelerated by NVIDIA RTX PRO Blackwell Embedded GPUs,...

Abnormal AI, the pioneer in AI-native human behavior security, announced it has been recognized as a Leader in the 2025 Gartner® Magic Quadrant™ for Email Security, marking the company&rsquo...

DigiCert, a pioneer in intelligent trust, unveiled its 2026 Security Predictions, forecasting how AI, quantum computing, and automation will reshape global trust frameworks. The predictions highlight...

Building on earlier research published in October 2025, Zimperium announced that its zLabs team has uncovered a significantly enhanced variant of ClayRat, an Android spyware family first detailed in t...

Iris officially launches today, introducing a platform that transforms how cameras are controlled, and productions are managed. By turning virtually any PTZ camera into a software-connected, remotely...

Secutech, Asia’s premier security exhibition, will be held from 22 – 24 April 2026 at the Taipei Nangang Exhibition Center, Hall 1. This edition promises a robust showcase of more than 400...

Hikvision announced recently that it has achieved the ISO 37301:2021 Compliance Management System certification from SGS, the world's renowned testing, inspection, and certification company. This mil...

Balancing operational efficiencies and customer satisfaction with costs, resources, and legislative obligations is a challenge faced by every security services provider offering keyholding and alarm r...

Axis Communications, a industry pioneer in video surveillance, announces it has signed the U.S. Cybersecurity & Infrastructure Security Agency’s (CISA) Secure by Design pledge to transp...

The Key To Unlocking K12 School Safety Grants

DownloadHoneywell GARD USB Threat Report 2024

DownloadPhysical Access Control

DownloadThe 2024 State Of Physical Access Trend Report

DownloadThe Security Challenges Of Data Centers

Download