Sony Security Camera Mounts (29)

Browse Security Camera Mounts

Security camera mount products updated recently

Security camera mounts - Expert commentary

With pupils in the UK set to go back to school on 8 March, there are a number of safety measures schools need to implement to ensure the health and wellness of the staff, students,...

Ergonomics are a critical, but often misunderstood aspect of designing control rooms for security. Ergonomics have a deep impact on the integrity of an operatio...

Endless possibilities for security deployment have been made possible with technological advancements Significant technological advancements have created endless...

Latest Sony Electronics’ Security Systems Division news

e-con Systems™, a globally renowned embedded camera company, launches RouteCAM_CU20, an HDR GigE ultra-low light camera with network synchronization capability. RouteCAM_CU2...

Immervision, the developer of advanced vision systems combining optics, image processing, and sensor fusion technology, announces the availability of its UAV (Unmanned Aerial Vehic...

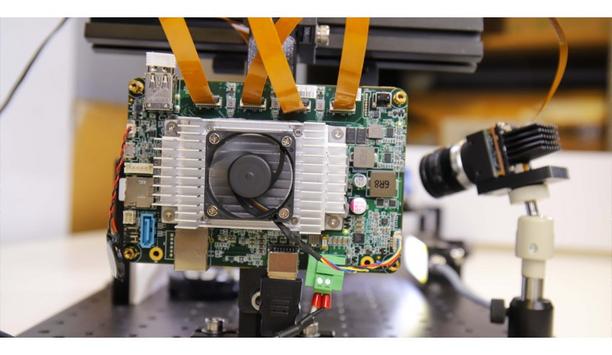

Embedded vision components are ever popular and being incorporated into a plethora of applications. What all these applications have in common is the need to pack more functionalit...

Trending topic articles

Zimperium, the world pioneer in mobile security, now released new threat research exposing a growing wave of mobile-targeted phishing attacks that weaponize PDF documents delivered via SMS and MMS....

Matrix Comsec, a pioneer in Security and telecommunications solutions, was honored with the “CII Award Excellence for Women in STEM 2025.” This prestigious award highlights Matrix's commi...

VITEC, a pioneer in IPTV and digital signage solutions, and Actelis Networks, Inc., a market pioneer in cyber-hardened, rapid deployment networking solutions for IoT applications, now announced a new...

WatchGuard® Technologies now announced the WatchGuard Zero Trust Bundle – a streamlined solution that finally makes zero trust achievable for organizations of all sizes. For y...

Fortinet®, the global cybersecurity pioneer driving the convergence of networking and security, now announced an integrated solution featuring FortiGate VM, Fortinet’s virtual cloud firewall...

dormakaba has signed a binding agreement to acquire Avant-Garde Systems Inc. (“Avant-Garde”), one of the largest independent solution providers for entrance systems control products in the...

Skills for Security has partnered with C-TEC to strengthen the training opportunities for apprentice fire and security technicians through greater access to current technologies and direct engagement...

Opengear, a Digi International company and a pioneering provider of secure and Smart Out of Band™ management solutions, announced now that it has achieved SOC 2 Type 2 and ISO 27001 compliance....

At CES 2026 in Las Vegas, demonstrations of Flir’s next-generation iXX-Series app-enabled thermal cameras will outline how users can transform electrical and mechanical inspections acr...

Allied Universal has sold a majority stake in AMAG Technology to Shore Rock Partners, a critical infrastructure-focused growth investor. AMAG is a global pioneer in integrated high-security access con...

Squire Locks USA has appointed Channel Championz, founded by security industry veteran Jerry Burhans, to lead its expansion into the North American critical infrastructure market. Burhans, a seasoned...

Netwatch, a provider of AI-powered security services, announced now that it has signed a definitive agreement to be acquired by GI Partners. Netwatch is a pioneering global provider of intelligent se...

Alibaba now unveiled the latest evolution of its visual generation models, the Wan2.6 series. It enables creators to appear in AI-generated videos as themselves and in their own voices with flexible...

In recent years, the development and adoption of AI technology has accelerated at an unprecedented pace, impacting various industries. Of course, the spark of innovation provided by AI is already a fe...

Matrix Comsec, a pioneer in Security and Telecommunication solutions, was honored with the CII Industrial Innovation Award 2025, recognizing Matrix as one of the Top 50 Most Innovative Companies in In...

The Key To Unlocking K12 School Safety Grants

DownloadHoneywell GARD USB Threat Report 2024

DownloadPhysical Access Control

DownloadThe 2024 State Of Physical Access Trend Report

DownloadThe Security Challenges Of Data Centers

Download