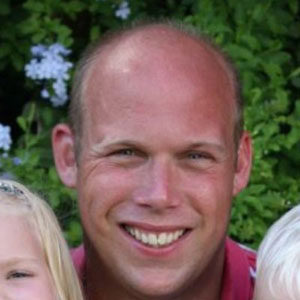

Adam Binns

Adam Binns

Managing Director, Binns Fencing Ltd.Adam Binns is MD at Binns Fencing Ltd and Chairman of the Association of Fencing Industries (AFI).

News mentions

UK’s renowned manufacturer and supplier of electronic and electrified perimeter security systems, Harper Chalice has added to its dealer network with what it describes as ‘one of its most...

Prison fence provider Binns Fencing Limited has notched up 80 years in existence – with the plan to double its turnover by the time it turns 100. History Of Binns Binns Fencing Limited, now a...

A third company has been accredited to install ArmaWeave, an approved high-security perimeter fencing system manufactured by Zaun. ArmaWeave Approved Installers Expert installers Allen Fencing Limit...