Xerafy News

Medical device manufacturers are pioneers in medical device tracking, digitizing loaner management to automate their consignment programs and support SPD traceability. Consigned surgical instrumentation and devices, such as ortho, implants, scopes, and laparoscopy, have become essential to healthcare facilities. Metal and plastic trays designed to handle and protect them during sterilization are now available with electronic tags that allow full tracking and digitalization of consignment progra...

Industrial RFID technology takes RFID past supply chain applications, into manufacturing and production, with more demanding applications, such as the high-temperature environments found in automotive industry. A properly designed RFID tracking system can significantly improve production efficiencies, control costs and streamline overall processes. Automotive provides a compelling example of a complex manufacturing process that involves numerous measures and steps, in order to ensure that what...

Recent industry surveys show that RFID-automated data center asset tracking can increase productivity 15 times while reducing the time used to inventory assets by as much as 90 percent. Comprehensive IoT solutions are available for data center automation to track and secure IT assets with very little human intervention, hence addressing the challenges of increasing inventory accuracy and decreasing time and physical labor. Limitations of barcodes for automation IT Assets case studies show how...

A recent regulation push for UDI in the U.S., EU, Australia/New Zealand, and China paves to way for the deployment of Surgical Tracking (SIT) systems in hospitals. The U.S. FDA is several years into its Unique Device Identifier (UDI) program for medical device tracking. Several other countries and regions have since been rolling out similar medical device tracking programs. The goal of these programs is to improve safety, increase efficiency, and provide unambiguous accountability when it comes...

Xerafy Xense offers Industrial IoT its new customizable platform to monitor and track assets in manufacturing, construction, infrastructure. Some of the key features of the new sensor tags include: A range of monitoring parameter options - Temperature (from -40° to +125°C with +/- 0.35°C resolution), Humidity, Strain, Ambient light, Pressure, Magnetic field (Hall Effect), Electrical continuity Industry-grade form factors and mounting options Battery-free operations RAIN RFID g...

Xerafy, the globally renowned company and innovator of Gen2 passive UHF RFID metal tags, has announced the launch of its updated MICRO series of on-metal tags, which are designed to meet the challenges of automation and digitization in manufacturing. Beyond identification and tracking, industrial RFID systems for manufacturing are moving towards automation, digitization, and data acquisition. MICRO series of on-metal tags The company’s flagship MICRO series offers tags that are all desi...

The manufacturer of seismic data acquisition equipment leverages Xerafy's embeddable RFID platform to provide its oil and gas customers worldwide with advanced tracking and location capabilities. The company (which has asked to remain unnamed) manufactures high-tech seismic data acquisition systems such as digital receivers, truck-mounted vibrators, seismometers, shooting systems, computer systems for signal graphic analysis, real-time quality control, etc. Tracking and collecting data in the...

Managing inventories of consumables and medical supplies come with a number of challenges for healthcare providers and some have been stepping up their games with IoT solutions. Healthcare providers are dedicating significant resources to the management of their consumables and medical supplies, commensurate with the challenges presented by the task as well as its critical nature when it comes to patient safety. Replenishing inventories, balancing costly inventory excess vs. patient-critical su...

Novo Surgical unveiled its first-generation RFID-enabled surgical instrument prototypes, at IAHCSMM 2017, in Nashville, Tennessee, USA. The prototypes are the result of month-long research and development efforts, by Novo Surgical’s engineering and quality control teams, and using patented Xerafy RFID technology. “We’re excited to present our first-generation of smart instruments developed in collaboration with Xerafy,” said Abed Moiduddin, the Vice President (VP) of Bus...

Government regulations mandate that all bottles of solution complete a rigorous sterilization process through an autoclave. Bottles of the solution must be sterilized at a temperature of 120°C for at least 10-15 minutes. Consequently, the production process must have strict documentation and control. If any batch is questioned in terms of having successfully completed the sterilization process, the entire batch must be discarded. Considering a bottle of the solution may cost around $110 and...

The company is a front-runner in building materials, operating around the world. It is well known for its finished cement boards, a high-tech mix of cement and fibres. The company’s US-based Project Manager responsible for developing and deploying the Work-In-Process RFID tracking system across their 8 North-American plants shared an update about the project. Challenges In order for the solution to be successful, four specific challenges have to be addressed: Substantial losses occur...

GD Medical is a medical supply OEM for major US healthcare companies, including Johnson & Johnson, Medtronics, Medline. In early 2020, it selected Xerafy, the RFID specialist, to custom design and produce an innovative RFID label that can withstand repeated gamma-ray radiation cycles. 2020 started with a surge in demand for PPE in the face of the COVID-19 pandemic and the acute challenges of accelerated shipments to institutions. Full vertical integration from raw material to global distrib...

To keep an automotive manufacturing operation running 24 hours a day, auto manufacturers have utilized Kanban systems, lean manufacturing and just-in-time manufacturing (JIT) however these business processes require tracking of the inventory and materials within a manufacturing facility. Manufacturers that truly want to automate the replenishment process utilize automatic identification such as RFID to create real-time visibility into their manufacturing and inventory management process. One su...

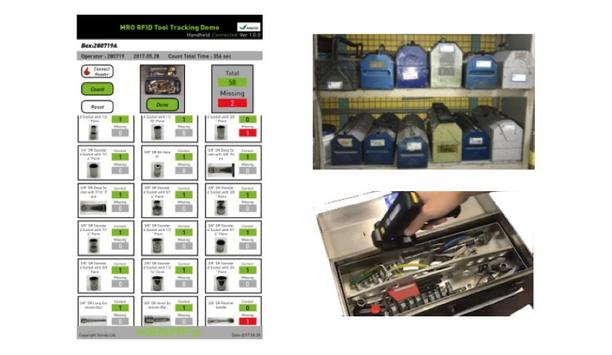

Hong Kong Aircraft Engineering Company (HAECO), one of the globally renowned independent aircraft engineering and maintenance companies, implemented a solution for full tool control and prevention of Foreign Object Detection (FOD) occurrences. HAECO selected Xerafy for its track record in the aviation industry, as well as the strong market experience and capabilities that the company has demonstrated in RFID tool control for MRO and FOD. MRO services HAECO provides maintenance, repair and ove...

Officers used to spend up to 15 minutes each shift recording the serial number from every radio, shotgun, citation printer, and other equipment. Before an officer of the Richardson (Texas) Police Department goes on patrol, he or she is responsible for verifying that everything that belongs in the squad car is there. Officers spent up to 15 minutes each shift recording the serial number from every radio, shotgun, citation printer, and other piece of equipment in the vehicle. Recording serial nu...

Passive RFID tags and mobile readers are cutting 70 percent of the time needed at this French nuclear power plant to locate tool containers, and 80 percent of the time needed to prepare regulatory reports. The Fessenheim nuclear power plant in the Alsace region of France has dozens of large, portable metal containers that store maintenance tools and equipment. The containers and their tool content are subject to numerous internal and regulatory controls for tool safety and security. The facilit...

Aman Aviation plans to drive the adoption of RFID-based tool control best practices in the Indian civil aviation sector, in partnership with Dolphin RFID and Xerafy. An increasing number of aviation companies are implementing RFID for MRO Tool Control, as a way of improving safety by automating Foreign Object Debris (FOD) detection and supporting Maintenance Repair and Operations (MRO) processes. RFID-based automated tool control system Aman Aviation's automated tool control system uses RFID...

The City of Mecca selected E-vision to deploy its innovative waste collection solution alongside 15,000 rugged Micro X-II RFID tags from Xerafy activated in the field. The Saudi Arabian city of Mecca has deployed Xerafy’s Micro X-II RFID tags to successfully manage thousands of waste collection bins. Using Xerafy’s rugged tags and a software solution from E-vision, the city now has real-time visibility into its waste collection activities and vehicle fleet. Mecca was looking for a...

TPV Group has deployed Xerafy's Roswell rugged RFID tags in its manufacturing process to improve efficiency and visibility in its manufacturing processes. TPV Group supplies body and chassis assemblies, seats and seat components, engine gaskets, and automated guided vehicle (AGV) solutions to automotive manufacturers. The company operates five production sites in Slovenia as well as one in Serbia and has more than 1,200 employees. Automatic identification integrator The company engaged Sloven...

The time and cost to trace more than 300,000 surgical instruments used in the Charité CFM Facility Management have been a big challenge for a long time. Instruments are easily mixed up even when they are sterilized or laser engraved, and devices can be difficult to read when contaminated. Also, it is not easy to service the instruments properly or document the product lifecycle. In February 2016, Charité finally found the solution and successfully deployed a ground-breaking surgic...

Greenville Hospital has deployed UHF RFID to help track expensive surgical instruments and other medical equipment to reduce losses and the time spent locating them. As the largest health care system located in South Carolina, Greenville Hospital System University Medical Center count 1,268 licensed beds, and 1,250 physicians out of 10,500 employees. The hospital has implemented EPC Gen 2 RFID tags to help identify surgical probes that are often accidentally thrown away after procedures. Becaus...

German manufacturer, Rittal deployed Xerafy's durable, high-temperature RFID tags in its paint shop operations, in order to track Work-In-Process (WIP) and automate stock tracking, and re-ordering with SAP. Rittal manufactures switch cabinets, air conditioning systems, and server and network cabinets. The lack of Work-In-Process (WIP) visibility into its painting processes led to manual stock checking and sub-optimal employment of its resources. Material purchases were based on historical estim...

Columbia University's College of Dental Medicine (CDM), one of the top dental schools in the U.S., is establishing itself as a leader in the use of RFID technology to drive compliance. The school launched the RFID project in response to a change in the way it managed dental instruments. Previously, students purchased their own dental instruments and were responsible for making sure each cassette (or dental instrument set) was complete and properly sterilized. Recently, the college transitioned...

Founded in 1966, New Zealand Company Skyline Enterprises Ltd is a global leisure operator with five sites in New Zealand, Singapore, and Canada. The company operates an inventory of thousands of luge carts, a purpose-built three-wheeled cart which is gravity-fueled, with the rider having control over speed and direction using a braking and steering system. The activity is fast-paced, with luge carts typically sustaining high levels of vibration and physical impact. As the carts are used and sto...

Integro's latest heavy-duty portable power equipment is industrial IoT-ready, thanks to source-tagging with embeddable Xerafy RFID. Industrial IoT innovation With its Paramount Kit, Integro LLC, a globally renowned company in power distribution solutions, brings industrial IoT innovation to portable power and other industries, by making it possible to reliably read an RFID tag from portable power equipment. Hubbell, a globally renowned company in electrical devices, is also launching its line...

The cost of manual instrument tracking was a primary driver for Charité-Universitätsmedizin Berlin, recognized as Germany’s best hospital. The time and cost of tracking 300,000 surgical instruments were growing at an unsustainable rate. In order to properly service and document instrument lifecycles, the hospital needed a technology that could bypass the identification and reading limitation inherent in contaminated instruments, while ensuring seamless tracking operations in t...

The Mexico City Police Department will deploy Xerafy Pico and XS Dot on-metal RFID tags for a weapons tracking application, which will improve the security and accountability of its armories. Xerafy’s partner in Mexico, Ofi Equipos PC, is spearheading the project. The RFID solution was adopted in an effort to address an ongoing problem, with the loss of police department weapons. Mexico City Police Department The Mexico City Police Department employs more than 34,000 officers, as well as...

Warwickshire College is one of the largest colleges of further and higher education in the Midlands region. Spread over six centers with 1,700 staff and 18,500 students needing support for both administration and learning facilities, Warwickshire College Information Services has a significant number of IT assets that have to be controlled across multiple sites. Challenges with IT asset management It has the twin problems of controlling the IT assets used by its administrative staff and those...

The 18-month pilot project at Rigshospitalet hospital in Copenhagen, Denmark, shows that tracking surgical instruments with RFID could save the hospital 31,000 hours a year in operating room procedures alone while also improving patient safety and providing additional time saving and infection control benefits during sterilization and other processes. Dr. Henrik Eriksen, project director for the RFID trial, announced the results last month during a press conference in Copenhagen. Implementing...

Xerafy’s RFID tags will track 11,000 surgical instruments and devices, improving productivity, reducing infection risk, and eliminating misplaced instruments. Ixtapaluca Hospital (HRAEI) in Mexico City is a 246-bed hospital with 13 surgical rooms, serving a community of five million people. UHF RFID tags deployed The Development and Operation of Hospital Infrastructure of Ixtapaluca (DOIHI), the asset management organization at the hospital, will use Xerafy’s UHF RFID tags, as part...