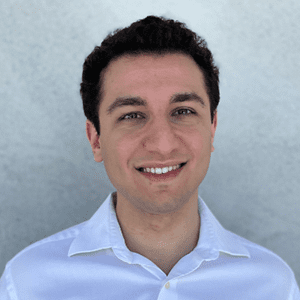

Adam Christie

Adam Christie

Design, Research and Development Manager, Zaun LtdAdam Christie is the Design, Research and Development Manager at Zaun. Adam is responsible for supervising the development of new, innovative products, managing the design team, streamlining design processes and providing staff and clients with technical support. He started his journey with Zaun as a Design Engineer. Adam holds a degree in engineering with specialization in design and innovation from Sheffield Hallam University.

News mentions

Steel mesh manufacturer Zaun has created an innovative high-security weldless mesh panel upgrade to steel palisade fencing. Research and Development Manager Adam Christie has devised an ingenious fast...

Two pioneers of perimeter protection, Rosehill Security and Zaun Limited, have joined forces to launch the latest in mobile hostile vehicle mitigation (HVM). The technology companies have combined the...

A high-security fence for rail and other critical national infrastructure applications that resists for more than five minutes of sustained attack with specialist power tools has been developed by ste...