The shift to renewable energy is here, and with it comes valuable infrastructure that needs protecting. Rain, dust, and other environmental factors are constant threats to outdoor equipment, and a quality gasket could be the difference between safe energy storage systems and costly damage.

Along with their sealing benefits, gaskets also provide vibration resistance and improve a door’s structural integrity. This keeps enclosures quiet and safe, no matter how much the internal machinery may hum.

Keep the outdoors out

One of the primary functions of gaskets in enclosure manufacturing is to provide environmental sealing. This is crucial for applications where dust, dirt, moisture, and other contaminants may compromise the integrity and functionality of the enclosed equipment.

By providing a tight seal, gaskets help to maintain the internal environment of the enclosure, ensuring that the equipment operates efficiently and reliably, and the outdoors stays where it belongs.

Cut the noise

Gaskets designed with good compression characteristics can dampen vibration and minimize rattle

Vibration is a common issue when it comes to enclosure manufacturing, as it can lead to abrasive noise and damage to sensitive equipment. Eliminating noise pollution is particularly necessary in residential areas, where homeowners must be assured the enclosure will not disturb their daily lives.

Gaskets designed with good compression characteristics can dampen vibration and minimize rattle. This not only enhances the operational life of the equipment but also improves the overall user experience.

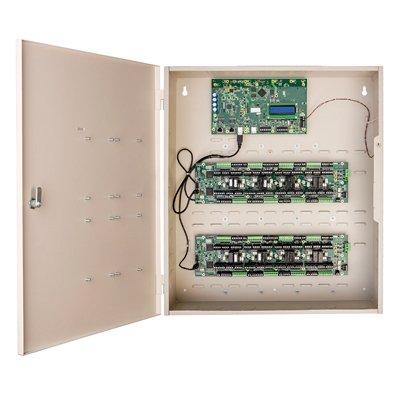

Enhancing structural Integrity and aesthetics

Gaskets, while primarily functional, also ensure clean lines and seamless integration of the enclosure components. The right gasket material and design can prevent unsightly gaps and misalignments between doors and frames, contributing to a polished and professional appearance.

Much like vibration resistance, the aesthetics of an enclosure can be integral to its success in residential areas. While temperatures can change over time, warping the enclosure’s metal exterior, gaskets remain malleable and provide increased tolerance for slight variations in a panel’s shape. This reduces maintenance costs and part replacement.

Choosing the right gasket and hardware

The importance of gaskets in enclosure manufacturing cannot be overstated. Their functionality ensures that enclosures are not only secure and accessible, but also well-protected from environmental factors and vibration damage.

But they are only part of a solution. Users judge devices based on how they physically interact with them. It is critical to combine a gasket with the right latch, hinge, and handle for a complete package that ensures a safe, high-quality experience for end users. As the demand for reliable enclosures continues to grow, these components will remain crucial in delivering solutions that meet the highest standards of performance and quality.